Client Background:North American ground store chain

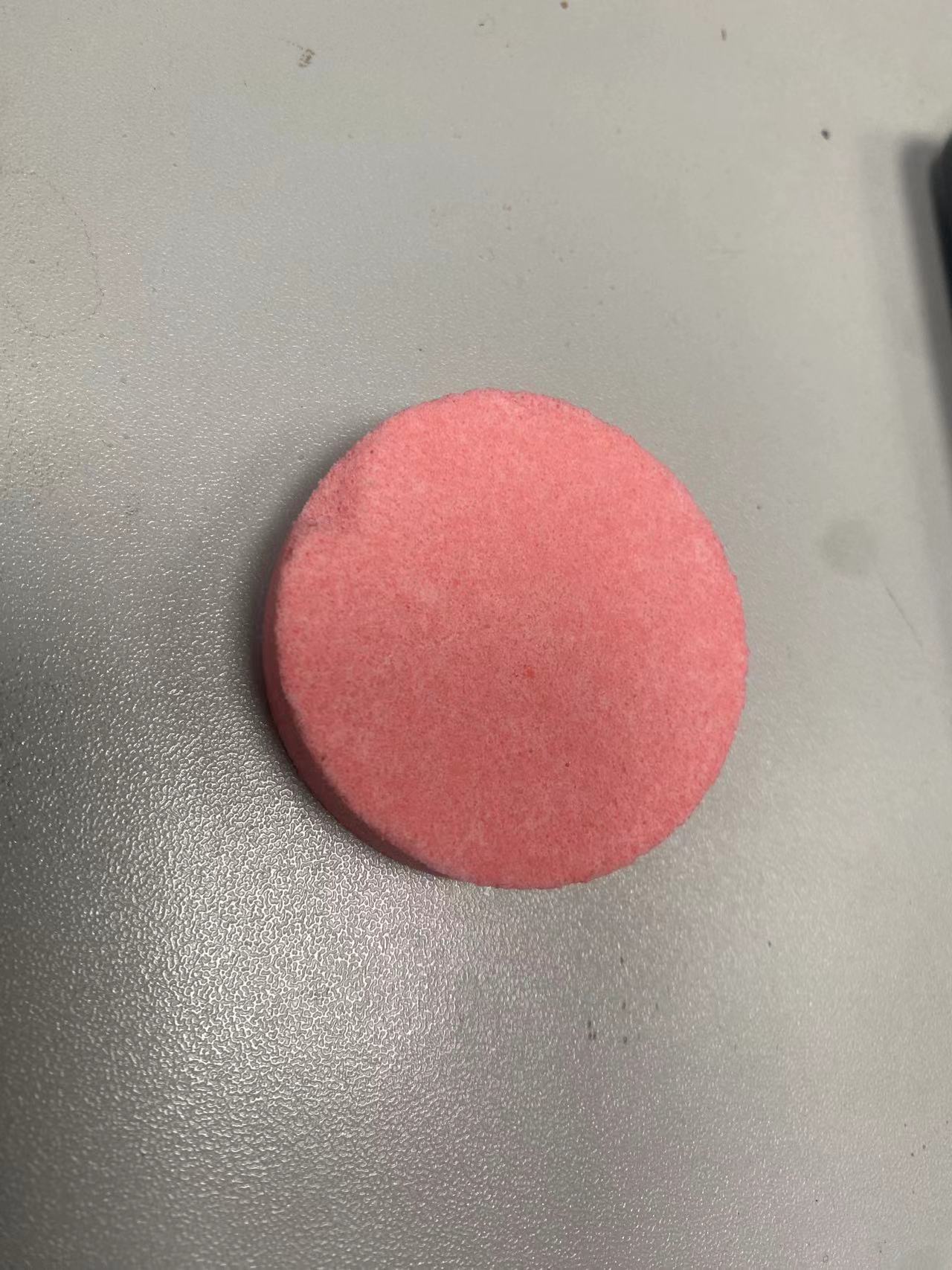

Product: 6% Aromatherapy Shower Tablets

Quantity: 100,000 tablets of 5 scents

Packaging: tinfoil wrapped products into heaven and earth lid boutique box

Quality inspection report: there is a gap in the corner of the product, sampling 300 pieces, defective rate of 31%

Problem analysis:

1. The mold is inspected before production to meet the production standards of large goods

2. The sampling inspection of the big goods production is qualified

3. The relative humidity of the dehumidification room is normal

The above links are in line with the factory production specifications, basically we can confirm that the problem occurs in the tail packaging link.

After engineering analysis, we found that the packaging used by the customer is heat shrinkable and wrapped in tinfoil, the product has high flavor content, and the flavor solidifies after dehumidification to make the product brittle, and the brittle product will be bumped in the heat shrink machine over the film, resulting in edge gap. Quality inspection in the process is not carefully spot-checked, resulting in the flow of defective products; when wrapping tinfoil process, the packaging department did not follow the requirements of sampling before packaging, the defective products for secondary process.

Solution:

1. defective rate exceeds the factory standard, the whole batch to do the destruction process.

2. Adjust the composition structure of the product to eliminate the characteristics of brittle products;

3. After the adjustment of the composition, do the expedited order processing, directly on the large goods.

4. strengthen the tail quality inspection efforts.

5. Suggest the customer to cancel the heat shrink, direct sampling inspection after wrapping tinfoil, reduce the heat shrink machine over the film will be bumped.

PS: quality inspection department, packaging department in charge of the accident again failed to achieve job responsibilities, the main responsibility, the monthly bonus unconditional deduction!

客户背景:北美地区连锁地面店

产品:6%香薰淋浴片

数量:5款香味合计10万片

包装方式:产品包锡纸入天地盖精品盒

品检报告:产品边角部分有缺口,抽检300片,不良率31%

问题分析:

1.模具在产前做检查符合大货生产标准

2.大货生产抽检合格

3.抽湿房相对湿度正常

以上环节均符合工厂生产规范,基本可以确认问题出现在尾部包装环节。

工程分析后发现客户使用的包装是热收缩后包锡纸,产品香精含量高,抽湿后香精凝固使产品脆化,脆化产品在热收缩机器过膜时会有磕碰导致边角缺口。品检在该工序上没有认真抽查,导致不良品流出;包锡纸工序时,包装部没有按要求抽检后再进行包装,将不良品进行二次工艺加工。

解决方法:

1.不良率超出工厂标准,全批次做销毁处理;

2.调整产品成分结构,消除产品脆化的特性;

3.成分调整后,做加急订单处理,直接上线大货;

4.加强尾部品检力度;

5.建议客人取消热收缩,直接抽检后包锡纸,减少热收缩机器过膜时会的磕碰。

PS:品检部、包装部负责人再此次事故中未能实现岗位职责,负主要责任,月度奖金无条件扣除!

返回:淋浴片

返回:淋浴片

淋浴片客户案例评价共创

淋浴片客户案例评价共创